We've partnered with FEC to add efficiency, accuracy, and depth throughout the Linear Asset Management process

Florida East Coast Railway (FEC) is a Class II regional railroad that owns all of the 351-mile mainline track from Jacksonville, FL, down to Miami. It is the exclusive rail provider for Port Miami, Port Everglades and Port of Palm Beach.

Background

In 2018, Brightline began operating passenger services between West Palm Beach and Fort Lauderdale, eventually expanding to Miami later that year.

As a result of FEC's growth in both freight and passenger transport, their engineering team began a transformation program which included the digitalization of Maintenance of Way processes. Through a competitive process, FEC management selected to partner with VisioStack to roll out the RailLinks® Linear Asset Management platform.

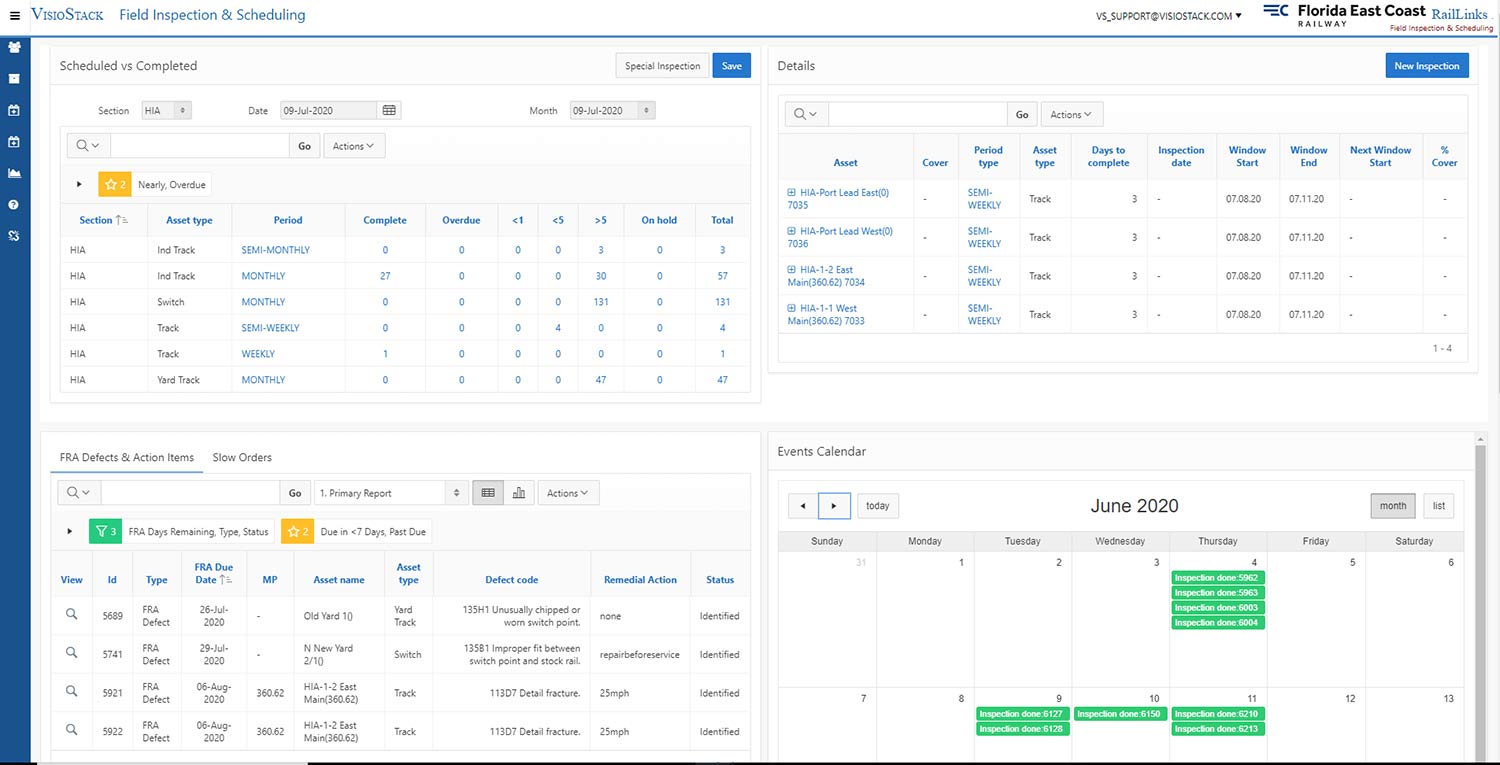

In 2019, VisioStack and FEC began a phased rollout of the RailLinks suite of Linear Asset Management Platforms. In its entirety, the platforms consist of Inspection and Scheduling, Infrastructure, Predict, AI (Artificial Intelligence), and Mobile, spanning user functions from field work to strategic capital planning.

As a result of FEC's growth in both freight and passenger transport, their engineering team began a transformation program which included the digitalization of Maintenance of Way processes. Through a competitive process, FEC management selected to partner with VisioStack to roll out the RailLinks® Linear Asset Management platform.

In 2019, VisioStack and FEC began a phased rollout of the RailLinks suite of Linear Asset Management Platforms. In its entirety, the platforms consist of Inspection and Scheduling, Infrastructure, Predict, AI (Artificial Intelligence), and Mobile, spanning user functions from field work to strategic capital planning.

"The platform's unique ability to correlate human activities to automated condition monitoring activities gives FEC a tremendous edge in the ability to predict, plan, and increase the availability of assets"

Understanding the Data

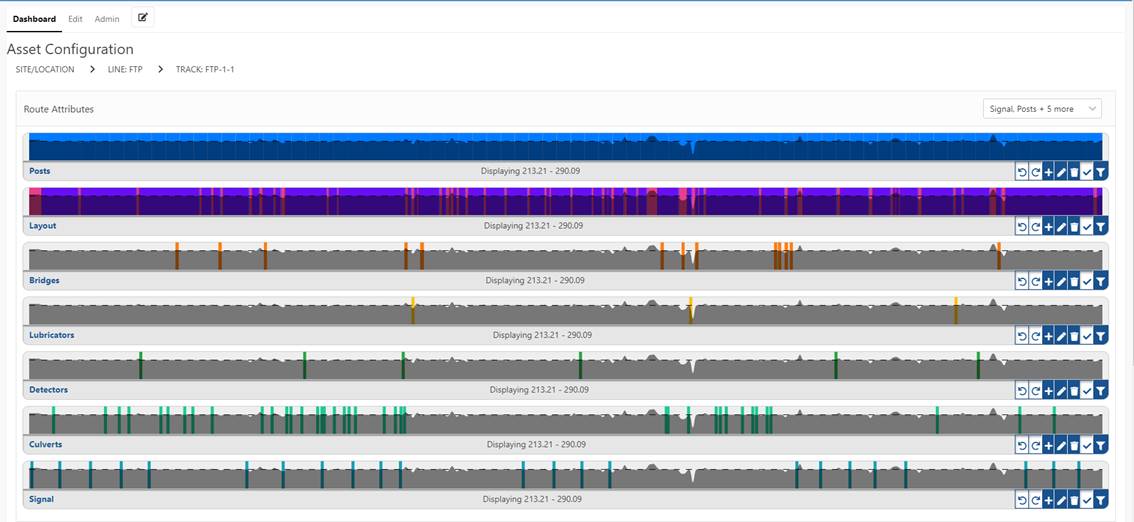

The primary effort in Phase I was the digitalization of inspection and maintenance record keeping. With RailLinks, record keeping begins with a detailed configuration of the network as a whole, understanding the relationships between asset structures. Through powerful linear asset visualizations, FEC began to build out its in-service asset inventory, ensuring that all key infrastructure assets were properly defined, localized, and tagged with associated attributes. Upon completion, FEC's ongoing inspection and maintenance activities are linked to the asset configuration, ensuring compliance against regulatory standards.

Through RailLinks, FEC's maintenance activities are also linked back to the service gangs performing the work, documenting the time, materials, and any effects on train movements. FEC employees and contractors began using the RailLinks platform to perform inspections, record work orders and track materials used, transforming disconnected, and often paper-based tasks into a digital, traceable process.

Through RailLinks, FEC's maintenance activities are also linked back to the service gangs performing the work, documenting the time, materials, and any effects on train movements. FEC employees and contractors began using the RailLinks platform to perform inspections, record work orders and track materials used, transforming disconnected, and often paper-based tasks into a digital, traceable process.

In parallel, RailLinks® Infrastructure was implemented to incorporate track geometry, rail wear, ground-penetrating radar and various types of imagery from automated inspection vehicles. FEC realized that the incorporation of Big Data from track-recording vehicles was fundamental to a predictive asset management program.

The platform's unique ability to correlate human activities to automated condition monitoring activities gives FEC a tremendous edge in the ability to predict, plan, and increase the availability of assets.

Towards the Future

In 2020, FEC added RailLinks® AI technology to the program. Based on available imagery streams, the platform is able to identify and report on occurrences typically found only in manual, visual inspections. The technology brings traditional field tasks back to the office, effectively reducing track occupancy and associated risk.

Want to know more about how RailLinks could benefit your railway? Reach out to us using one of the methods below: