Automated Efficiency

Cloud workflows are key

From data ingestion processes to receive new condition information, to detection of new in-service rail types using the latest in Artificial Intelligence, RailLinks has been constructed from the ground up to facilitate automated decisions.

As organizations increase their use of advanced, "intelligent" sensors, the amount of data available to improve maintenance decisions increases. Our cloud workflow framework provides the foundation for automation to make meaningful use of all this data.

Data-Driven Asset Performance

Intelligent assets extend life cycle

More condition data is collected on railway infrastructure than ever before. Traditional linear measurements like track geometry are now accompanied by new technologies such as tie assessment and ballast fouling. In addition, imaging systems are now being deployed in autonomous modes in an effort to improve manual inspections and reduce track occupancy.

Each of these individual technologies offer a limited, siloed approach to asset performance. In contrast, RailLinks® Predict provides a global view of the railway system in its entirety.

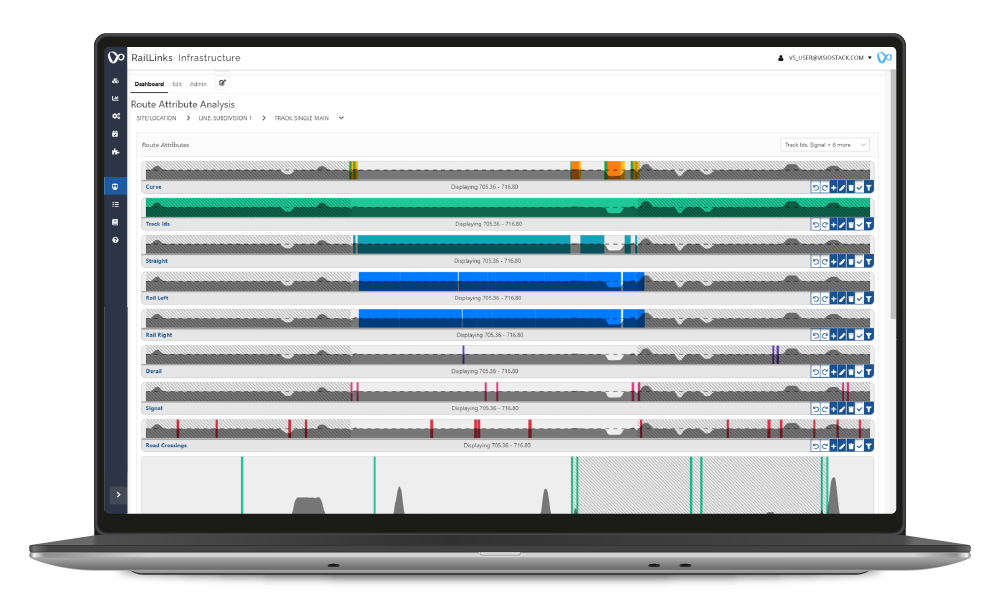

Accurate Inventory & Material Usage

Meet the assets you never knew

One of the challenges of railway Linear Asset Management is understanding what you're working with. RailLinks not only provides a modern approach to configuring, editing, maintaining and visualizing railway assets, it also provides tools to supplement and fill in asset attributes that were never known before.

Examples include accurately identifying track layout such as straights, transitions, and curvature attributes, as well as identifying rail type information through the use of artificial intelligence. This information is critical in automating accurate and reliable predictions.

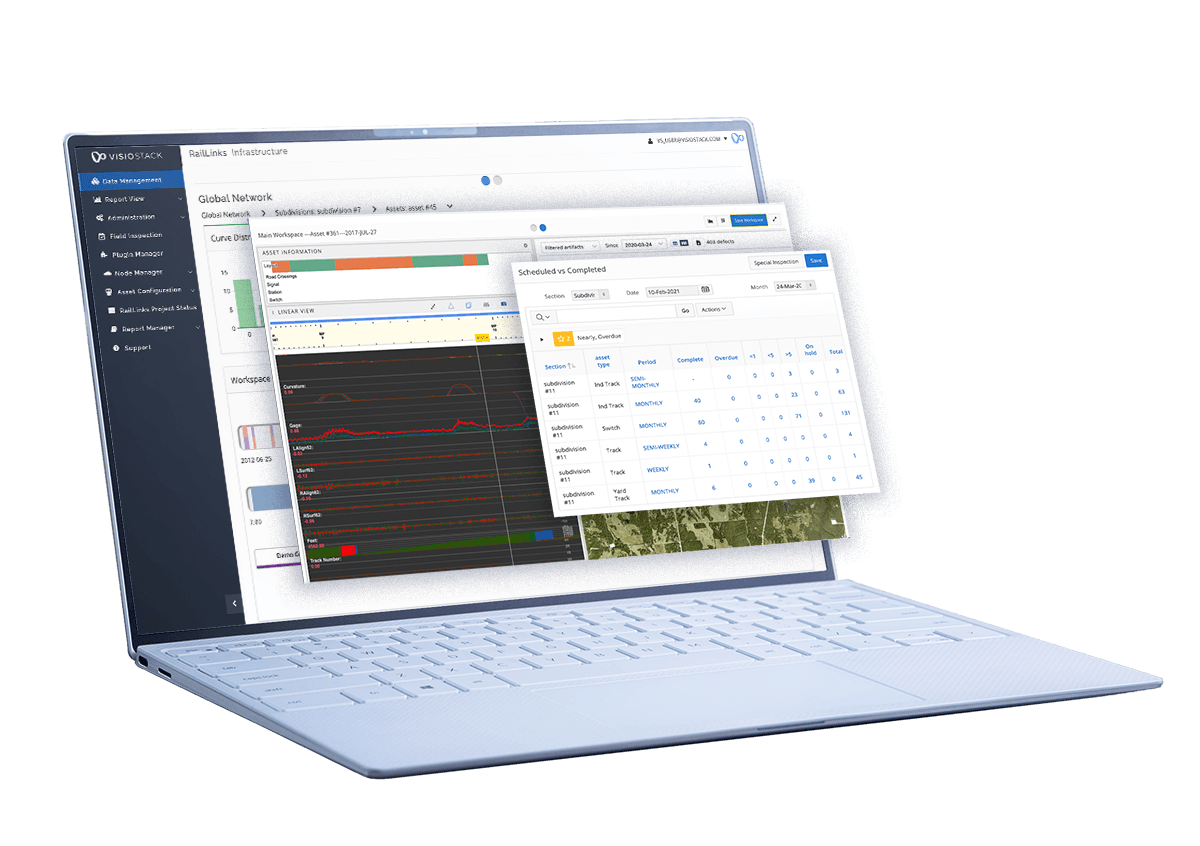

Improved Planning & Scheduling

Welcome to hassle-free scenario analysis

Our industry-leading analysis examines your whole network to understand how fast your critical assets wear out. Use our interactive reporting framework to run scenarios on future network use, and fine-tune your renewal and replacement strategies. We give you the tools to plan for today and tomorrow, backed by years of underlying historical data from the entirety of your asset base.

Optimized Workforce Management

The proof is in the data

The effectiveness of maintenance operations is measured by the resulting asset performance. Railway Linear Asset Management must close the cycle of measure, assess, maintain—and yes, audit effectiveness. RailLinks is able to detect changes in asset condition data and tie the events back to a maintenance work order and track asset performance from that point in time.

Additionally, RailLinks can optimize where critical maintenance assets should be used by prioritizing work by proximity of available machines.

Organized Regulatory Compliance

Prioritized Inspection Scheduling

Never lose track of upcoming asset inspections. With the foundation of a interactive asset repository, automated or manual inspections can be scheduled against any asset. Track frequency of inspections and quickly access the latest results.

Regulatory Defect Tracking

RailLinks® Field Inspection and Scheduling integrates regulatory standards with actionable inspection activities to make sure your organization remains in compliance.

Daily Reporting

Track field work activities that tie back to inspection results. Forecast work plans for future schedules, slow orders, equipment delays, train delays, travel time, scrap location and details, as well as many other maintenance-related activities.